Insights into our daily work

Müri Prototech has continuously invested in new technologies since being founded in 1951, and our employees are committed and enthusiastic to meet the challenges of rapid innovation and technical progress.

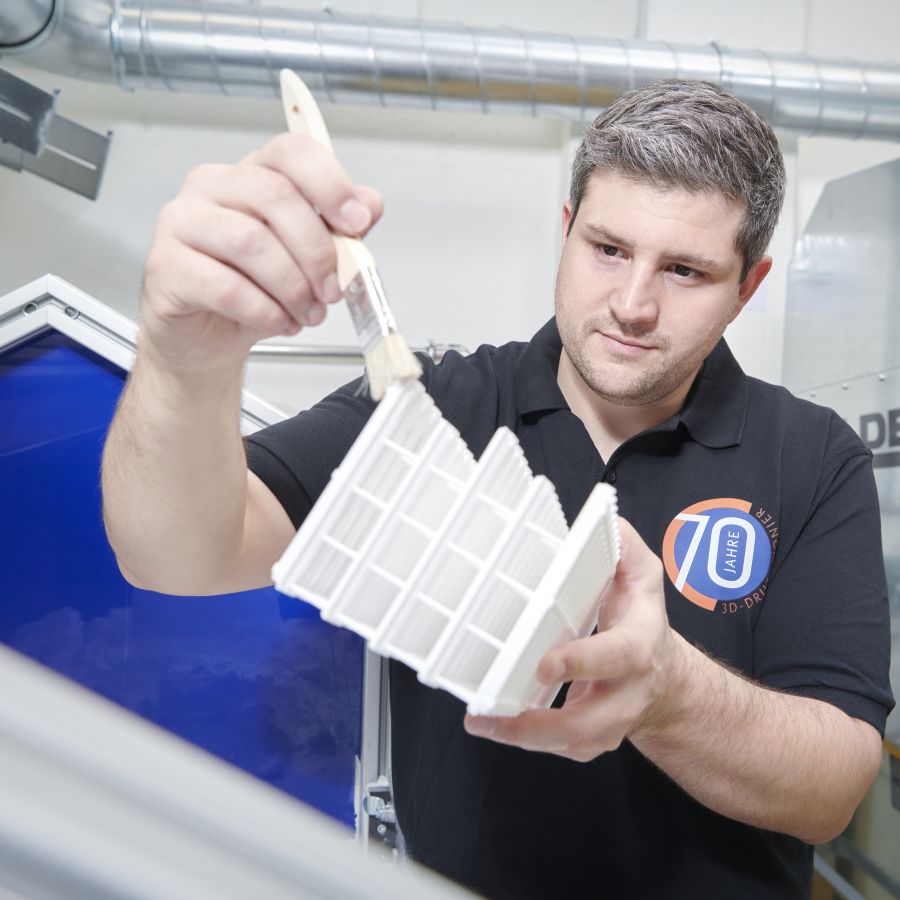

We are committed to the investment in training of apprentices and passing on the fine skills of custom prototyping which we have been making over decades, and continue to invest in order to remain at the forefront of technology.

A strong team

Everyone can achieve their goal together at Müri - be it employees who support each other, partners who benefit from our capacity to innovate, or customers who are able to realise an idea with us.

This embodies our brand – check it out for yourself in the video on the left.

People make the difference

Motivated employees in consulting, administration and production are our most valuable asset. We offer young people prospects and attract new talent to our team by continuously training apprentices.

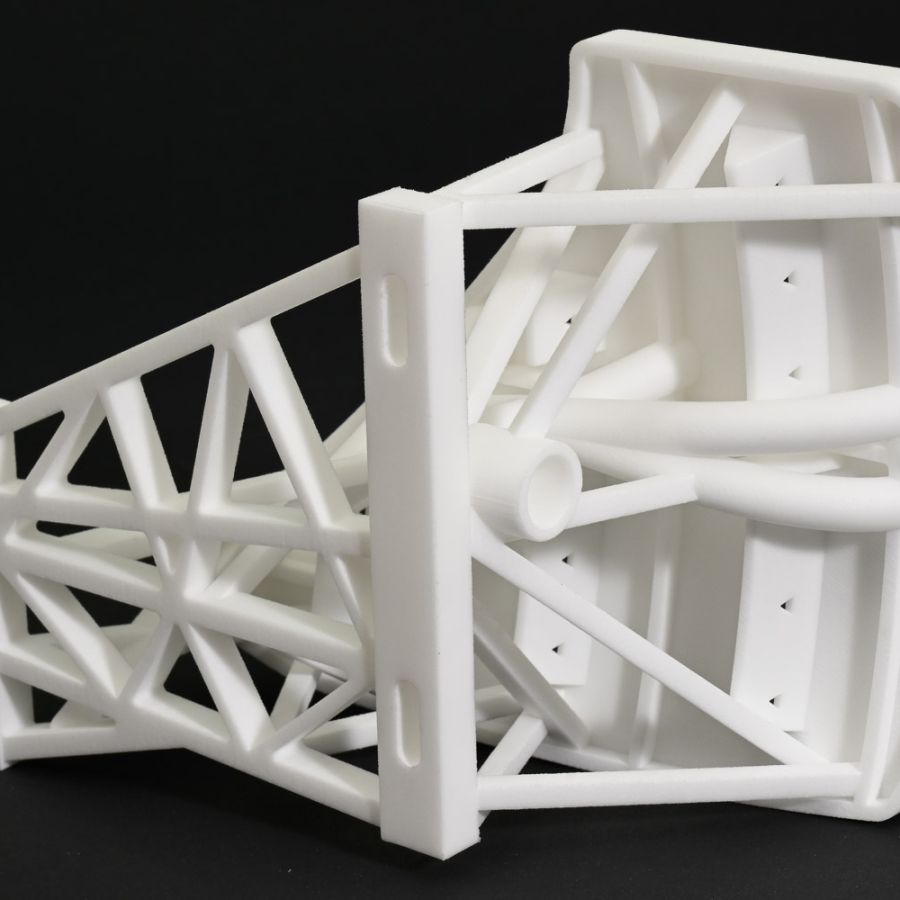

By regularly investing in modern machines and systems, we offer both customers and employees the ideal environment for a wide range of development opportunities for the production of prototypes and small series.

Our multiple technologies include

- 3D-Printing (selective laser sintering SLS and Stereolithography SLA)

- HSC milling

- Vacuum moulding and low-pressure moulding (RIM)

- Large variety of surface treatments

Innovating since 1951

Company founded by Arthur Müri

Introduction of low-pressure moulding process (RIM)

Company succession to 2nd generation, Martin Müri

Commissioning of the first vacuum moulding system in Switzerland

New business premises in Mattenfeld, introduction of CNC milling technology

Ralf Müri, Martin Müri's son, joins the family business then with eight employees.

Introduction of SLA3500 stereo lithography process

Commissioning of first 5-axis machining centre

QS certification ISO 9001:2000

Introduction of SLS Vanguard HS laser sintering technology

Commissioning of Viper Si micro-stereo lithography

Extension project North with expansion of production and CAD/CAM areas. Relocation and expansion of CNC production

Commissioning of own coating facility

Launch of largest SLA system in Switzerland, iPro8000

South extension expanding production area and offices to 2500m² in total

Expansion of 5-axis milling area

Opening of clean room for 3D printing parts for medical sector

Conversion and expansion of 3D printing in SLS, introduction of 3D scanning and reverse engineering

ISO 14001:2015 quality certification

Refurbishment and expansion of CNC production Commissioning of new 5-axis milling centre with pallet system and robot

Jennifer Müri, daughter of Ralf Müri, joins the family business, which by now has 23 employees.

Andreas Heinimann and Ralph Hunziker join the management team.

Müri is where people come together. People with ideas and skills working together in dialogue to transform the shared information into a cohesive form as a prototype. Our brand overhaul aims to clearly demonstrate this.